Exhibition Review: We Shined at The Global Sources Hong Kong Electronics Show and Gained This!

We’ve Just Returned from the Show

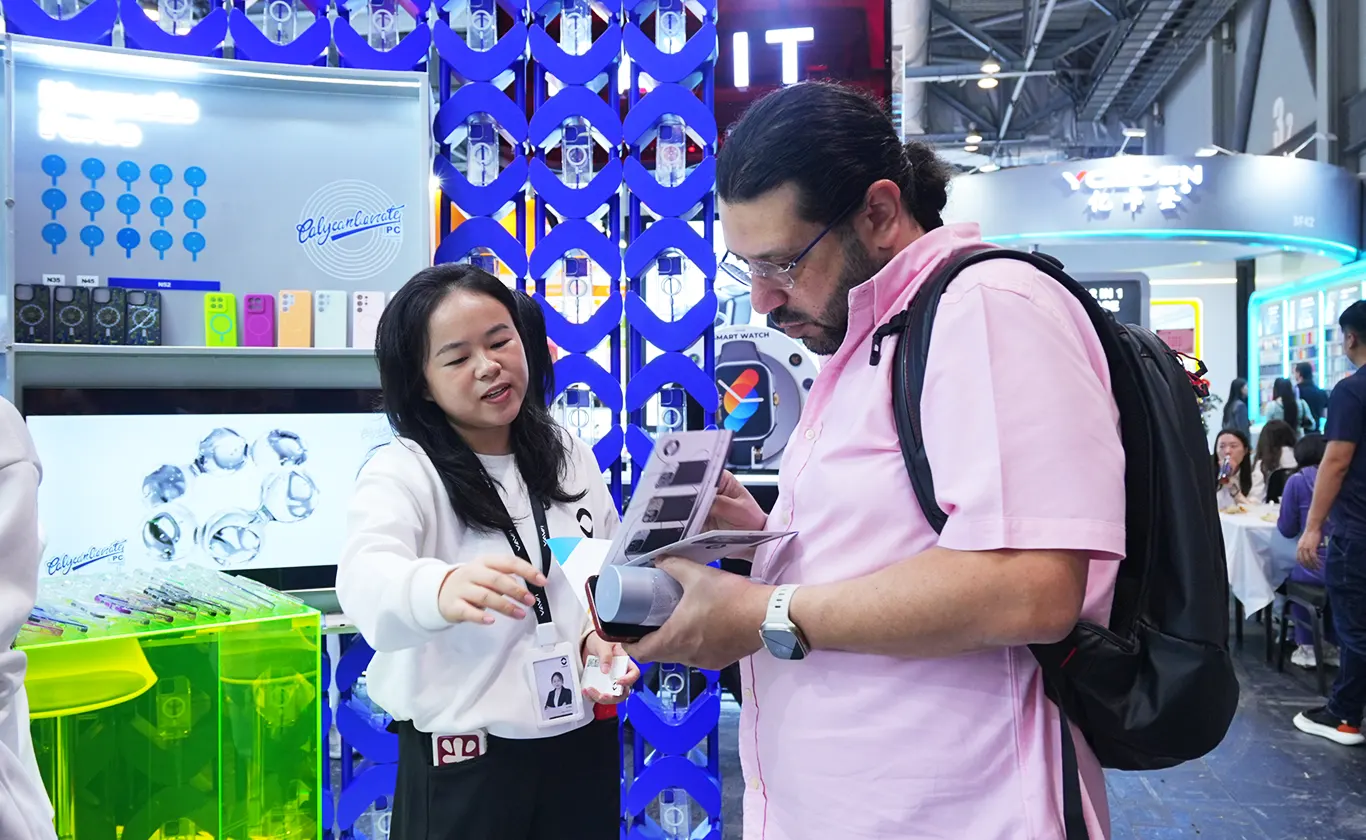

As a leading mobile phone case manufacturers, combining the production strength of a phone case factory with the personalization capabilities of a custom phone case service provider, our team has just returned from the Global Sources Mobile Electronics Show 2025 in Hong Kong. Over four days of high-intensity meetings and observations, we not only showcased our latest product lines but also gained deep insight into the phone case trends 2025. The diversity and customization demands of today’s market have never been clearer, and we are more confident than ever about our next steps in product development and wholesale strategy.

Event Highlights & Key Results

- 350+ global buyers consulted on-site, generating broad brand exposure

- 325 qualified leads collected, spanning North America, Europe, Middle East and Southeast Asia

- 36 preliminary cooperation agreements signed, laying a solid foundation for mass production and supply-chain integration

Armed with these tangible metrics and on-site feedback, we will now present a comprehensive, in-depth industry analysis to help you choose the right mobile phone case manufacturers and guide you through the actual operations of a phone case factory and the custom phone case process.

Industry Status & Market Opportunities

Global Market Size & Growth

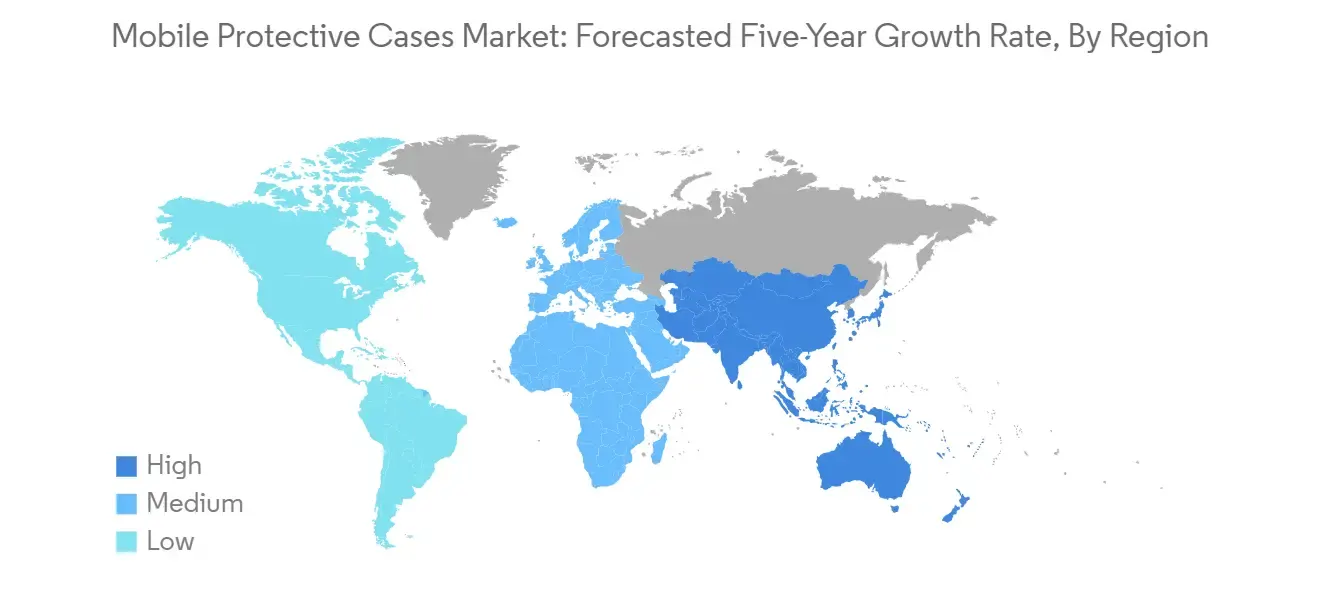

Smartphone penetration continues to rise, driving rapid expansion in the accessories sector. According to authoritative reports, the global phone case market surpassed US$20 billion in 2024 and is growing at a 7% CAGR, projected to exceed US$30 billion by 2028.

- Geographic distribution: The European and American markets are highly mature, with strong demand for custom phone cases and functional phone cases. The Asia-Pacific region, especially emerging markets such as China and India, are more sensitive to cost performance. The Middle East and Latin American markets prefer fashionable patterns and customized wholesale services.

- Consumer groups: Millennials and Generation Z have become the main groups. The demand for personalization, fashion, and functionality is constantly upgrading.

Market opportunities

- Customization: Demand for DIY design, IP co-branding, themed gifts, etc. continues to heat up;

- Functionalization: MagSafe magnetic suction, bracket, antibacterial, wireless charging and other functional mobile phone cases are rapidly expanding;

- Environmental protection and sustainability: biodegradable TPU, PLA materials and green packaging have become brand differentiation selling points;

- Channel diversification: Online direct sales, self-operated e-commerce, distribution and wholesale, overseas warehouses and e-commerce platforms are all carried out simultaneously.

Combined with the first-hand feedback we collected at the exhibition, brands and wholesalers can start with the above four opportunities and quickly lay out the product strategy for the next quarter.

How to Choose the Right Mobile Phone Case Manufacturers

From our interactions with dozens of mobile phone case manufacturers, we have identified five core capabilities that truly meet the needs of modern brands and distributors:

1. Perfect quality management system

- International certification: ISO 9001, BSCI, Sedex and other certifications, as well as OK Compost, EU Ecolabel and other qualifications for environmentally friendly materials.

- Inspection process: strictly implement incoming material inspection, first piece inspection, process inspection and full shipment inspection, and support third-party factory inspection.

- Traceability management: from raw materials to finished products, each batch can be traced back to the corresponding test report and traceability code.

2. Strong design and R&D capabilities

- Customized design team: with plane and 3D design capabilities, quickly respond to the creative needs of brand owners.

- Mold manufacturing and maintenance: self-built mold workshop, equipped with CNC, wire cutting, laser cutting equipment, support an average of 10+ new molds per month.

- Quick proofing: complete real machine samples in 3-5 days, and can be converted to mass production within 7-10 days, shortening the listing cycle.

3. Stable production capacity and transparent delivery

- Capacity scale: daily production capacity can reach 30,000+ pieces, and monthly production capacity can reach one million pieces.

- Production scheduling management: ERP system real-time order tracking, support mixed production and night shift system.

- Delivery guarantee: regular order batch delivery in 7-14 days, urgent orders can be completed in 3-5 days.

4. Reasonable quotation and cost transparency

- Transparent cost structure: mold fee, process fee, material fee, and packaging fee are clear at a glance.

- Mass production preferential policy: annual purchase volume tiered discount, 95% off, 90% off, 15% off.

- Multi-process price comparison: for different budgets, provide UV printing, screen printing, thermal transfer, laser engraving and other solutions.

5. Integrated customer service and logistics support

- 24/7 response: professional after-sales team, seamless service across time zones.

- Overseas warehouses and multimodal transport: overseas warehouses are deployed in North America, Europe, the Middle East and other places, supporting multiple trade methods such as DDP, EXW, FOB, CIF, etc.

- Technical training and information sharing: provide distributors with product training videos, sales script templates, and marketing promotion material packages.

In summary, when choosing the right mobile phone case manufacturers, quality, R&D, production capacity, cost and service should be comprehensively considered to ensure smooth and efficient cooperation.

OEM Phone Case vs. Custom Phone Case: What’s the Difference

A common question at the show was, “What’s the difference between an OEM phone case and a custom phone case, and which suits my brand best?”

| Dimension | OEM Phone Case | Custom Phone Case |

|---|---|---|

| Definition | Mass production based on client-supplied artwork or molds | Fully tailored design process from scratch |

| MOQ | ≥ 1,000 pieces | ≥ 100 pieces (some simple lines ≥ 50 pcs) |

| Design Input | Client supplies final design files | Manufacturer offers creative & iterative design support |

| Unit Cost | Lower per unit | Higher per unit, premium positioning |

| Lead Time | 7–15 days per batch | 5–10 days per batch |

When to Choose OEM:

- The brand has perfected the design: there is already a mature brand vision and packaging plan.

- High cost sensitivity: a large amount of inventory is required, and cost-effectiveness is the main competitive advantage.

- Stable supply chain: focus on long-term stable supply relationship.

When to choose Custom Phone Case?

- Focus on differentiation: IP co-branding, theme event gifts, limited co-branded models.

- Quick test: new product promotion on e-commerce platforms, short-term market testing.

- Functional innovation: MagSafe bracket combination, antibacterial function, wireless charging compatible design.

By clearly distinguishing OEM and Custom, it can not only help buyers formulate precise strategies, but also allow phone case factories to optimize service processes according to customer needs.

In-Depth Analysis of 2025 Phone Case Trends

At the Hong Kong Global Sources Electronics Show, we surveyed dozens of booths and summarized the following six phone case trends 2025. These trends will guide the product layout of mobile phone case manufacturers and wholesalers in the coming year.

Trend 1: MagSafe magnetic attraction and multi-function integration

- Compatibility: Maintain a perfect fit with Apple MagSafe standard accessories.

- Multi-function: Integrated card slot, bracket, wireless charging module, lanyard interface, etc.

- Material technology: Metal frame combined with flexible lining to achieve comfortable grip and magnetic stability.

Trend 2: Creative patterns and IP cross-border joint

- Trendy cooperation: Many exhibitors cooperate with well-known illustrators and street artists to launch limited editions.

- Customization platform: Provide real-time gallery and design tools online, support C2M (Customer to Manufacturer) model.

- Gift market: The demand for customized gift mobile phone cases for enterprises has surged, bringing new opportunities for B2B customization.

Trend 3: Sustainable and environmentally friendly materials

- Material innovation: Application of bio-based materials such as PLA, PHA, and degradable TPU.

- Packaging upgrade: Paper inner packaging, degradable plastic film and water-based printing in parallel.

- Certification standards: Formal certifications such as OK Compost, EU Ecolabel, and US FDA enhance credibility.

Trend 4: Antibacterial and health and safety

- Antibacterial coating: Silver ion and copper ion antibacterial technology is mature.

- Test report: ISO 22196 antibacterial performance test is qualified.

- Application scenarios: Targeted promotion in medical institutions, schools, and public places.

Trend 5: Small batch 3D printing and on-demand production

- Flexibility: Support small batch rapid proofing of 10-50 pieces.

- C2M mode: Users upload designs online and directly generate 3D printing models.

- Cost advantage: Reduce losses and meet the ultimate customization experience.

Trend 6: Lightweight and minimalist aesthetics

- New materials: graphene-enhanced composite materials, carbon fiber textures.

- Ultra-thin design: thickness controlled below 1.2mm, and high drop resistance.

- Surface treatment: anti-fingerprint, anti-yellowing, matte and frosted textures coexist.

Understanding and grasping the above phone case trends 2025 will help manufacturers and wholesalers accurately launch products that meet trends and market needs.

Key Elements of a Phone Case Factory

Combining the sharing of industry leaders and customer feedback at this exhibition, we have summarized five key factors for evaluating a top phone case factory:

Mold manufacturing and maintenance capabilities

Self-built mold workshops are the core of improving proofing speed and product consistency. High-end factories are equipped with CNC machine tools, wire cutting machines and laser cutting equipment. Ensure that the mold accuracy is within ±0.05mm and can be maintained and upgraded in the shortest time.

Professional R&D team and innovation capabilities

Excellent R&D teams can not only understand market trends, but also transform ideas into mass-produced products. Combined with 3D proofing, real machine testing and structural simulation, break the “design-production” barrier and achieve new products online within 15 days.

Multi-process fusion production

From UV printing to screen printing, thermal transfer, laser engraving, to supporting 3D printing small batch production. Flexibly switch production processes to meet the needs of different customers for pattern quality and speed.

Standardized management of the entire process

Implement 6S on-site management and ERP system integration. From order receipt, production scheduling, quality inspection to logistics shipment, every step is visualized and traceable. Ensure that the shipment qualification rate reaches more than 99.8%.

Wholesale and logistics integrated services

Have overseas warehouses or mature cross-border logistics partners. Deploy overseas warehouses in key markets such as Europe, America, the Middle East, and Southeast Asia. Support multiple trade terms such as DDP, DDU, EXW, FOB, CIF, etc., to help wholesalers improve final distribution efficiency and reduce overall costs.

Service Process of a Custom Phone Case Manufacturers

As a factory and wholesaler, our custom phone case manufacturers service process has been optimized many times in practice. The current standardized process is as follows:

Demand docking: quickly implement customer needs through B2B templates obtained from exhibitions. Including models, quantity, materials, patterns, packaging and certification requirements.

Creative design: Provide flat and 3D renderings. Combine the trend elements of phone case trends 2025 to ensure that the design is competitive in the market.

Fast proofing: Complete the first batch of samples in 3-5 days. Provide high-definition shooting and functional test reports to facilitate customers to make decisions.

Mass production scheduling: ERP system automatically schedules production, delivers in batches, and provides real-time progress screenshots.

Quality inspection: three-level process of first-piece acceptance + process inspection + full inspection of shipments, with inspection reports.

Warehousing and logistics: multiple warehousing solutions, select the best logistics route based on customer needs, and provide tracking numbers and after-sales support.

The above process can be flexibly adjusted according to the customer’s personalized needs to ensure efficient connection between customization and wholesale business.

Environmental Trend: The Rise of Environmentally Friendly Phone Cases

Under the global environmental protection wave, environmentally friendly phone cases are moving from niche to mainstream. Exhibition data shows that more than 60% of buyers expressed strong interest in green materials and sustainable packaging.

Material and process innovation

- Bio-based materials: Optimized ratio of PLA, PHA and degradable TPU, taking into account flexibility, drop resistance and degradability.

- Green packaging: Use renewable paper materials and biodegradable plastic films to reduce plastic waste.

- Water-based ink and printing: Replace traditional solvent-based inks to achieve zero VOC emissions in the printing process.

Certification and traceability

- International standards: OK Compost, EU Ecolabel, US FDA, REACH, ROHS and other certifications.

- Scan code traceability: The packaging is printed with a QR code, and consumers can check the source of materials and degradation cycle in real time.

Circular economy and recycling system

- Used shell recycling: Cooperate with third-party recycling agencies to establish online recycling guidelines and preferential exchange mechanisms.

- Closed-loop utilization: Recycle materials and reuse them to reduce dependence on natural resources.

- Brand charity: Organize recycling activities with environmental protection organizations to enhance brand reputation.

Grasping the development of environmentally friendly mobile phone cases not only conforms to the trend of consumption upgrading, but also can obtain more government and platform policy support.

Frequently Asked Questions

For personalized customization or market testing, our service supports a minimum of 100 pieces (some simple styles as low as 50 pieces).

For mass production, the standard delivery time is 7–14 days; urgent post-show orders can be expedited to 5–7 days.

We implement full traceability on raw materials and finished batches, and print a QR code on each package for on-demand verification.

and offer flexible trade terms (EXW, FOB, CIF, DDP) so you can choose the optimal delivery and clearance solution.

Conclusion & Call to Action

Returning from the Global Sources Mobile Electronics Show 2025, we have integrated every insight—from custom phone case creativity to OEM phone case efficiency—into our next-generation offerings. Whether you seek innovative functionality, eco-credentials, or trend-right designs, partner with us to turn these opportunities into sales and competitive advantage.

Contact us now to join hands with a professional custom phone case manufacturers and one-stop supply chain to turn new trends into sales and competitive advantages.

Read more related articles:

- The Ultimate Guide to Wholesale Phone Cases: Scientific Selection from Material to Design.

- A Must-read for Newbies! 5 Pitfall Avoidance Guides for Wholesale Phone Case Purchases.

- 10 Key Questions About Phone Case Factory Docking Fully Answered.

- Factory direct supply vs distributor: Why is it more cost-effective to choose the source supply chain?

- How to Bulk Buy Phone Cases: A Complete Guide for Retailers and Distributors.

- Phone Cases Where to Buy? A Practical Guide to Buying From the Source Factory.

TPU

TPU Tablet

Tablet Kevlar

Kevlar Filp

Filp Airpods

Airpods Wallet

Wallet Watch Band

Watch Band